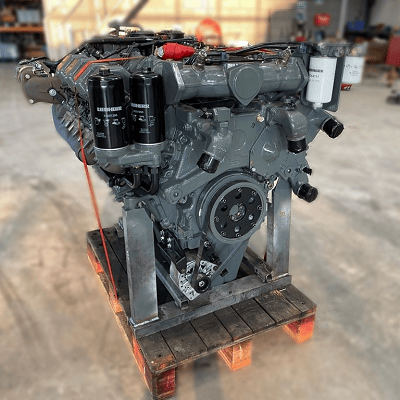

When it comes to heavy machinery, reliability and power are paramount. Liebherr, a name synonymous with innovation and excellence in engineering, stands tall as a pioneer in the realm of heavy equipment and machinery. From towering cranes to robust excavators, Liebherr’s engineering prowess extends to the heart of these machines. We delve into the world of dyno testing a Liebherr engine, uncovering the meticulous process behind unleashing the raw power concealed within. Before we embark on the journey of dyno testing, it’s crucial to understand the foundation upon which Liebherr engines are built. With decades of engineering expertise and commitment to quality, Liebherr engines are crafted to withstand the most demanding environment and deliver unparalleled performance. Each component is meticulously designed and rigorously tested to ensure reliability, efficiency and longevity. 1 Preparation: The engine undergoes meticulous preparation before being mounted onto the dynamo meter. This includes ensuring all connections are secure, fluids are filled to the appropriate levels, and sensors are properly calibrated. 2 Mounting: The engine is carefully mounted onto the dynamometer, a specialized device designed to simulate real-world operating conditions. Precision is paramount during this step to ensure accurate results. 3 Initial checks: Once mounted, a series of initial checks are conducted to verify proper alignment, connection integrity, and functionality of all engine systems. 4 Warm-up: The engine is started and allowed to warm up to operating temperature. This ensures consistent results and minimizes the risk of damage during testing. 5 Baseline testing: With the engine warmed up , baseline tests are conducted to establish initial performance metrics. This includes measuring power output, torque, fuel consumption, and emissions at various RPM levels. 6 Load testing: The engine is subjected to progressively increasing loads to simulate different operating conditions, such as idle, partial load and full load. This allows engineers to assess performance across the entire operating range and identify any potential issues or optimization. 7 Data analysis: Throughout the testing process, data is continuously collected and analyzed in real-time. Advanced instrumentation and software are used to monitor performance metrics and identify trends or anomalies. 8 Optimazation: Based on the data analysis, adjustments may be made to optimize engine performance. This could involve fine-tuning fuel injection timing, adjusting air-fuel ratios, or optimize turbocharger boost pressure. 9 Validation: Once testing is complete, the results are meticulously reviewed and validated against predetermined criteria and specifications. Any deviations or anomalies are thoroughly investigated to ensure accuracy and reliability. 10 Reporting: Finally, a comprehensive report is generated detailing the results of the dyno testing, including performance metrics, observations, and any recommendations for further optimization or refinement. Dyno testing a Liebherr engine is more than just a routine procedure – it’s a testament to the unwavering commitment to excellence that defines Liebherr’s engineering philosophy. By subjecting their engines to rigorous testing and analysis, Liebherr ensures that each engine delivers the uncompromising performance, reliability, and efficiency that customers expect. In conclusion, dyno testing a Liebherr engine is not just about measuring power output. It’s about unlocking the true potential of these remarkable engines and ensuring they exceed expectations in the most challenging environments imaginable.

Folding high-altitude work vehicles have been in the market for nearly 20 years. Due to their pure mechanical operation, they are simple, sturdy, and durable. This type of high-altitude work vehicle can also be called a curved arm high-altitude lifting vehicle, which is used for outdoor wiring and street light installation and maintenance. The working height is usually between 13 meters and 22 meters. The large arm can rotate 360 degrees, the hanging basket can rotate 180 degrees, and there is a set of manual operating rods at the turntable and in the basket, Used to control the upward, downward, and rotational movements of the boom, one person can also use this vehicle for high-altitude operations.

The blue brand aerial work vehicle produced by our factory adopts a hydraulic 360 degree full rotation, three folding arms, a single hydraulic lifting cylinder, with a two-way balance valve, an electrically controlled lifting arm, and an adjustable support leg with a two-way hydraulic lock.

For the 13 meter high-altitude work vehicle, we refer to the following standards:

The supplier shall use the latest national and industry standards issued and implemented, and may use other standards with the consent of the user

3. Environmental conditions for use

13 Meter Aerial Work Platform,Aerial work platforms,Telescopic Boom Lift,Articulating Boom Lift Hubei Yingrun Automobile Co., Ltd , https://www.aerialworkvehicle.com

The process of a dyno test on a Liebherr engine

The foundation of excellence

The process

The outcome of dyno testing

(The leg operation is manual and can be controlled separately) with a 0.5 ton hook.

Main features:

1. The boom and support legs are both made of low alloy Q345 profiles, with no welds around them. They have a beautiful appearance, high stress, and high strength;

2. The H-shaped leg has good stability and can be operated simultaneously or independently. It is flexible to operate and can adapt to various working conditions;

3. The rotary mechanism adopts an adjustable type for easy adjustment;

4. The turntable rotates 360 ° in both directions and adopts advanced worm gear reduction mechanism (with self-lubricating and self-locking functions), which can be easily maintained in the later stage by adjusting the bolt position to achieve the desired effect;

5. The boarding operation adopts an integrated electronic control valve block mode, with a beautiful layout, smooth operation, and convenient maintenance;

6. Get off and get on interlocking, safe and reliable operation;

7. The boarding operation is achieved through a throttle valve to achieve infinite speed regulation;

8. The hanging basket adopts an external pull rod mechanical leveling, which is more stable and reliable;

9. The turntable and hanging basket are equipped with start and stop switches, which are easy to operate and save fuel;

Can achieve higher standards. According to industry standards, provisions have been made for product quality, and the performance of the products provided by the supplier should meet national standards. When there is a deviation between the clauses in the above standards and these technical conditions, these technical conditions shall prevail.

The following standards are cited:

1) GB/T9465 Aerial Work Vehicles

GB3766 General Technical Conditions for Hydraulic Systems

2) GB7258 Technical Conditions for Safety of Motor Vehicle Operation

3) GB1589 "Load and Mass Limits for External Dimensions of Vehicles"

4) GB4785 Installation Regulations for External Lighting and Light Signal Devices of Motor Vehicles and Trailers

5) GB11567.1.2 "Requirements for side and rear lower protection of automobiles and trailers"

6) QC/T252 "Specification for Type Approval Testing of Special Purpose Vehicles"

7) JB/ZQ3011 General Technical Conditions for Welding of Construction Machinery

8) JG5099 Safety Rules for High Altitude Work Machinery

9) CCAP-C11-01-2014 Implementation Rules for Compulsory Product Certification for Automobiles

1) Altitude: ≤ 1000 meters

2) Environmental temperature: -5 ℃~+40 ℃

3) Relative humidity: ≤ 95% (25 ℃)

4) Seismic resistance: Ground horizontal acceleration of 0.3g

Ground vertical acceleration of 0.15g acting simultaneously for three consecutive sine waves with a safety factor of 1.67

5) Maximum daily temperature difference: 15 ℃

6) Sunlight intensity (at wind speed of 0.5m/s): 0.1W/cm2 7) Maximum wind speed: ≤ 10.7m/s1

4. Main technical parameters Basic upper garment configuration Set

Arm form: Three section folding arm

Material profile Q345B/4mm

Arm cross section quadrilateral

Fluctuation angle 0 ° -70 ° (relative to the horizontal plane)

The maximum working height of the working condition is 13m

At maximum operating height

Assignment amplitude of 3m

Maximum homework amplitude of 6.2m

At maximum homework amplitude

The homework height is 8.6m

Double directional 360 ° continuous rotation

The maximum lifting weight of the lifting arm is 1000Kg

The maximum lifting height is 6.8m

Hook 1T

Support legs, front and rear H-shaped

Support leg material profile Q345B/5mm

Leg span longitudinal (mm): 3240, transverse (mm): 3180

The four legs of the hydraulic lock are equipped with bidirectional hydraulic locks

Rear leg strobe light yellow; Two

The carriage is made of high-quality carbon steel and profiles, covered with 3mm anti slip patterned steel plates

Toolbox 1200 * 400 * 500; Mold stamped door with stainless steel door lock

Fence Φ 20 stainless steel pipes

Step up and down steps on the side of the driver's cab

High quality carbon steel cold-formed profiles for side and rear protection; High strength

window.authenticationPopup = {"autocomplete":"off","customerRegisterUrl":"https:\/\/www.cranepartssupply.com\/en\/customer\/account\/create\/","customerForgotPasswordUrl":"https:\/\/www.cranepartssupply.com\/en\/customer\/account\/forgotpassword\/","baseUrl":"https:\/\/www.cranepartssupply.com\/en\/","customerLoginUrl":"https:\/\/www.cranepartssupply.com\/en\/customer\/ajax\/login\/"}

{

"#authenticationPopup": {

"Magento_Ui/js/core/app": {"components":{"authenticationPopup":{"component":"Magento_Customer\/js\/view\/authentication-popup","children":{"messages":{"component":"Magento_Ui\/js\/view\/messages","displayArea":"messages"},"captcha":{"component":"Magento_Captcha\/js\/view\/checkout\/loginCaptcha","displayArea":"additional-login-form-fields","formId":"user_login","configSource":"checkout"}}}}} },

"*": {

"Magento_Ui/js/block-loader": "https\u003A\u002F\u002Fwww.cranepartssupply.com\u002Fstatic\u002Fversion1728988868\u002Ffrontend\u002FComaxx\u002FPartsSupply\u002Fen_US\u002Fimages\u002Floader\u002D1.gif"

}

}

{

"*": {

"Magento_Customer/js/section-config": {

"sections": {"stores\/store\/switch":["*"],"stores\/store\/switchrequest":["*"],"directory\/currency\/switch":["*"],"*":["messages"],"customer\/account\/logout":["*","recently_viewed_product","recently_compared_product","persistent"],"customer\/account\/loginpost":["*"],"customer\/account\/createpost":["*"],"customer\/account\/editpost":["*"],"customer\/ajax\/login":["checkout-data","cart","captcha"],"catalog\/product_compare\/add":["compare-products"],"catalog\/product_compare\/remove":["compare-products"],"catalog\/product_compare\/clear":["compare-products"],"sales\/guest\/reorder":["cart"],"sales\/order\/reorder":["cart"],"checkout\/cart\/add":["cart","directory-data"],"checkout\/cart\/delete":["cart"],"checkout\/cart\/updatepost":["cart"],"checkout\/cart\/updateitemoptions":["cart"],"checkout\/cart\/couponpost":["cart"],"checkout\/cart\/estimatepost":["cart"],"checkout\/cart\/estimateupdatepost":["cart"],"checkout\/onepage\/saveorder":["cart","checkout-data","last-ordered-items"],"checkout\/sidebar\/removeitem":["cart"],"checkout\/sidebar\/updateitemqty":["cart"],"rest\/*\/v1\/carts\/*\/payment-information":["cart","last-ordered-items","captcha","instant-purchase"],"rest\/*\/v1\/guest-carts\/*\/payment-information":["cart","captcha"],"rest\/*\/v1\/guest-carts\/*\/selected-payment-method":["cart","checkout-data"],"rest\/*\/v1\/carts\/*\/selected-payment-method":["cart","checkout-data","instant-purchase"],"customer\/address\/*":["instant-purchase"],"customer\/account\/*":["instant-purchase"],"vault\/cards\/deleteaction":["instant-purchase"],"persistent\/index\/unsetcookie":["persistent"],"review\/product\/post":["review"],"wishlist\/index\/add":["wishlist"],"wishlist\/index\/remove":["wishlist"],"wishlist\/index\/updateitemoptions":["wishlist"],"wishlist\/index\/update":["wishlist"],"wishlist\/index\/cart":["wishlist","cart"],"wishlist\/index\/fromcart":["wishlist","cart"],"wishlist\/index\/allcart":["wishlist","cart"],"wishlist\/shared\/allcart":["wishlist","cart"],"wishlist\/shared\/cart":["cart"],"catalog\/customproduct\/add":["cart"],"braintree\/paypal\/placeorder":["cart","checkout-data"],"braintree\/googlepay\/placeorder":["cart","checkout-data"]},

"clientSideSections": ["checkout-data","cart-data"],

"baseUrls": ["https:\/\/www.cranepartssupply.com\/en\/"],

"sectionNames": ["messages","customer","compare-products","last-ordered-items","cart","directory-data","captcha","instant-purchase","loggedAsCustomer","persistent","review","wishlist","recently_viewed_product","recently_compared_product","product_data_storage"] }

}

}

{

"*": {

"Magento_Customer/js/customer-data": {

"sectionLoadUrl": "https\u003A\u002F\u002Fwww.cranepartssupply.com\u002Fen\u002Fcustomer\u002Fsection\u002Fload\u002F",

"expirableSectionLifetime": 61,

"expirableSectionNames": ["cart","persistent"],

"cookieLifeTime": "3600",

"updateSessionUrl": "https\u003A\u002F\u002Fwww.cranepartssupply.com\u002Fen\u002Fcustomer\u002Faccount\u002FupdateSession\u002F"

}

}

}

{

"*": {

"Magento_Customer/js/invalidation-processor": {

"invalidationRules": {

"website-rule": {

"Magento_Customer/js/invalidation-rules/website-rule": {

"scopeConfig": {

"websiteId": "1"

}

}

}

}

}

}

}

{

"body": {

"pageCache": {"url":"https:\/\/www.cranepartssupply.com\/en\/page_cache\/block\/render\/page_id\/268\/","handles":["default","cms_page_view","cms_page_view_id_the-process-of-a-dyno-test-on-a-liebherr-engine"],"originalRequest":{"route":"cms","controller":"page","action":"view","uri":"\/en\/the-process-of-a-dyno-test-on-a-liebherr-engine"},"versionCookieName":"private_content_version"} }

}